|

|

MEMBRANE APPLICATIONS |

MENU

|

MEMBRANE APPLICATIONS |

||

|

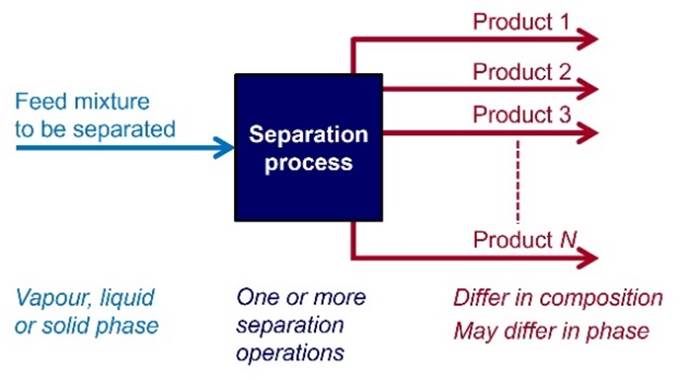

SEPARATIONS Almost every element or compound is found

naturally in an impure state, as a mixture that needs to be separated into its

individual components. Common industrial separation processes include

distillation, crystallization, liquid-liquid extraction, absorption,

adsorption and membrane processes. |

|

|

10-15% of the world’s energy consumption is used

in separations. Some separation processes, such as distillation, are very energy

intensive. New techniques, such as membrane processes, can

reduce energy use, lessen environmental impact, and provide more sustainable

ways to obtain what we need. |

|

|

|

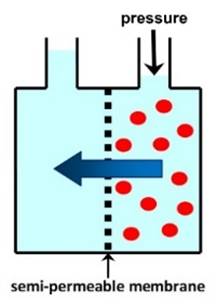

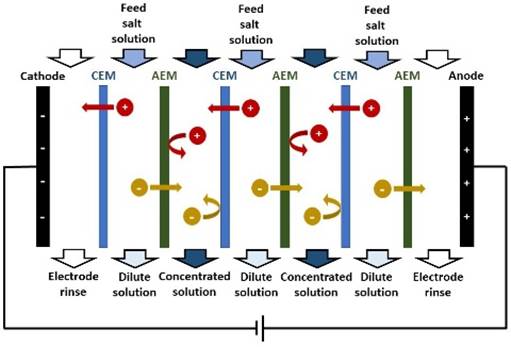

DESALINATION Membranes may be used to remove sodium chloride

and other ions from seawater (salt concentration 3-4%) or brackish water

(salt concentration <3%), to provide clean water for drinking or other

uses. The main technique used for desalination of

seawater is REVERSE OSMOSIS. Other membrane processes used for desalination include

ELECTRODIALYSIS. |

|

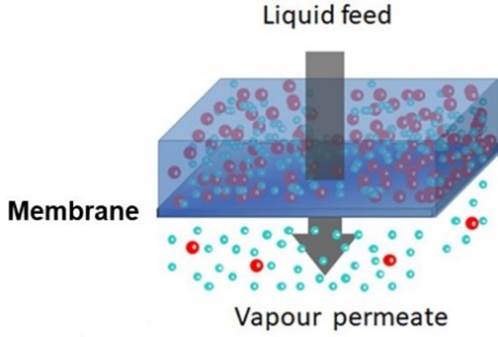

DEHYDRATION Some mixtures are particularly

difficult to separate by conventional methods. For example, you cannot obtain

pure ethanol by simple distillation of a mixture with water, because an

azeotrope is formed that is 95.6 wt.% ethanol. PERVAPORATION may be used to

remove water and achieve purer ethanol. |

|

|

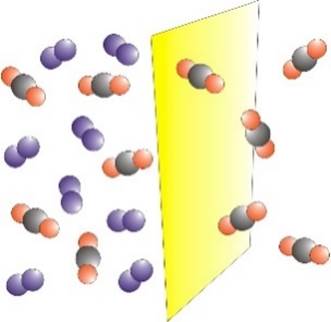

GAS SEPARATION Membranes may be used to

separate a mixture of gases. The process is driven by a difference in

pressure across the membrane. One of the first large-scale

applications of membrane gas separation was for the recovery of hydrogen in

the production of ammonia. |

|

|

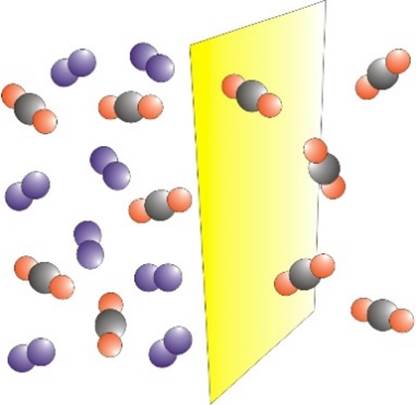

CARBON DIOXIDE CAPTURE In order to reduce greenhouse

gas emissions, CO2 may be separated from flue gases or other

sources, to be utilised in useful products or stored in geological

formations. The most highly developed

technology for CO2 capture from flue gases is amine-based

absorption. Membrane systems, which are relatively simple and compact, are

being developed for this application. |

|

|

GAS TREATMENT Membrane systems may be used

to remove CO2 and other impurities from natural gas or biogas. |

AIR

SEPARATION Air is 78% N2 and 21% O2 by

volume, with small amounts of other gases. Air separation membranes are used to

create a nitrogen enriched inert gas, to reduce the risk of explosion, for

example in aircraft fuel tanks. Air separation membranes may also be used to

generate an oxygen enriched gas for industrial or other processes. |

|

FUEL CELLS A

fuel cell converts the chemical energy of a fuel into electrical energy. A

fuel cell continues to produce electricity as long as the fuel is supplied. In

a fuel cell an electrolyte is sandwiched between two electrodes. A fuel (e.g.

H2) is fed to the anode and an oxidant (e.g. O2 in air)

is fed to the cathode. |

PROTON-EXCHANGE MEMBRANE A proton-exchange membrane (PEM),

also called polymer electrolyte membrane (PEM), conducts protons but acts as

a barrier to other species and is an electronic insulator. A PEM may be used as an

electrolyte in a hydrogen-oxygen fuel cell. A commercial polymer commonly

used as a PEM is Nafion. Nafion is a copolymer of tetrafluoroethylene and a

perfluoro(vinyl ether) unit modified to give a sulfonic acid group. |

|

|

|