|

|

GAS SEPARATION |

MENU

|

GAS SEPARATION |

||

|

GAS

SEPARATION APPLICATIONS Gas separation membranes are used for applications such as: Air separation for generating nitrogen. Hydrogen recovery in ammonia production. CO2 removal from natural gas. |

INERT

GAS GENERATION Many aircraft have an on-board inert gas generating

system. A membrane module is used to

generate a nitrogen-rich inert gas from air. The inert gas is fed into the

fuel tank to prevent ignition of fuel vapours. |

|

MEMBRANE MATERIALS A membrane material must offer: SELECTIVITY so there is a separation. PERMEABILITY so the required membrane area is not too large. PROCESSABILITY so membranes can be fabricated economically. GOOD MECHANICAL PROPERITES so the membrane doesn’t fall apart. CHEMICAL AND THERMAL STABILITY so the mebrane

survives conditions of use. RESISTANCE TO AGEING, PLASTICIZATION AND FOULING so the membrane

maintains its performance over time. |

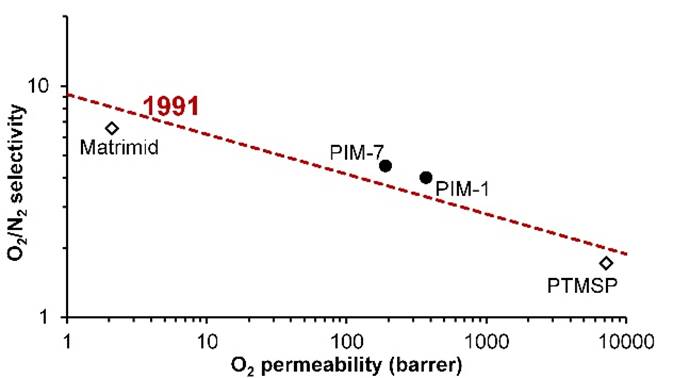

ROBESON PLOT Efforts to increase

selectivity often lead to a loss of permeability and vice versa. There

is a trade-off between these two properties. For gas separation membranes,

the trade-off between selectivity and permeability can be represented on a

double logarithmic plot. In 1991 Lloyd Robeson drew the

upper bound of performance that could then be achieved with polymer membranes

for various gas pairs. |

|

O2/N2

ROBESON PLOT Conventional membrane

polymers, such as the polyimide Matrimid, have low

permeability. The substituted polyacetylene

poly[1-(trimethylsilyl)-1-propyne] (PTMSP) has very high permeability, but

low selectivity. In 2005, two polymers of

intrinsic microporosity (PIMs) were shown to surpass the upper bound of

performance. |

L.M. Robeson, J.

Membr. Sci., 1991, 62, 165. P.M. Budd et al., J.

Membr. Sci., 2005, 252, 263. |

|

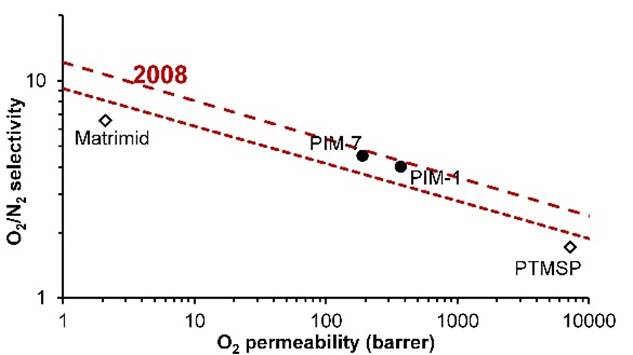

L.M. Robeson, J. Membr.

Sci., 2008, 320, 390. |

In 2008, Robeson revised the

upper bound. |

|

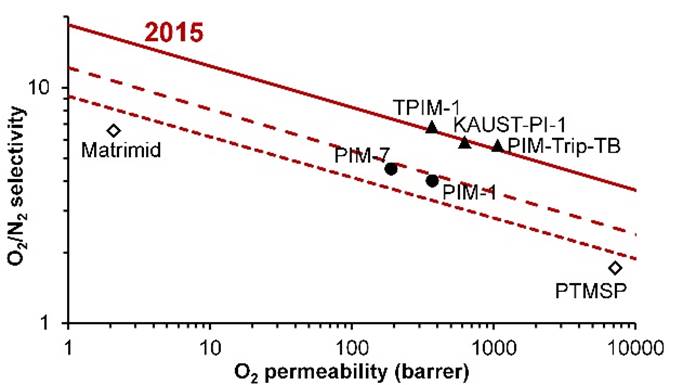

Further developments in PIMs led to a new upper bound being

proposed in 2015. |

R. Swaidan

et al., ACS Macro Lett., 2015, 4,

947. |

|

B. Comesana-Gandara

et al., Energy Environm. Sci., 2019, 12, 2733-2740. |

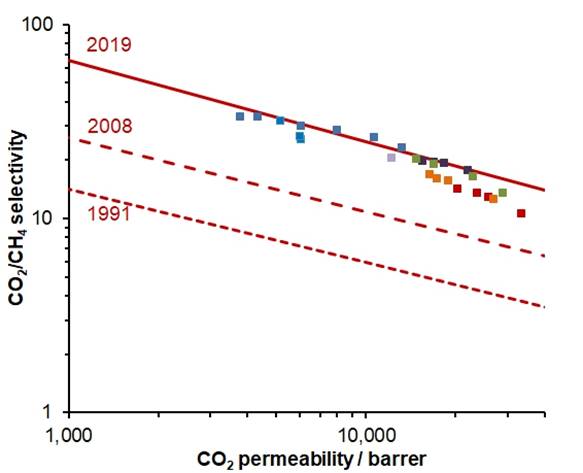

CO2/CH4

ROBESON PLOT In 2019, new upper bounds were proposed for CO2 separations, based on

ageing data for membranes of benzotriptycene-based

PIMs. |

|

You can find gas permeation data for many membrane materials in

a database maintained by CSIRO. |

|

|

Machine-learning can be used to predict gas permeability and other polymer

properties. |

|

|

Gas separation membranes are often based

on glassy polymers. High free volume, glassy polymers such as PIMs offer the

prospect of very permeable membranes, but for commercial application the

issue physical ageing, which leads to a loss of permeability over time, needs

to be addressed. |

gas permeation properties,

physical ageing, and Its mitigation in high free volume glassy polymers |

|

To improve performance, a filler may be added

to a polymer, giving a mixed matrix membrane (MMM), or two different polymers

may be blended together. |

seeking synergy in

membranes: blends and mixtures with polymers of intrinsic microporosity |

|

|

|