|

|

|

|

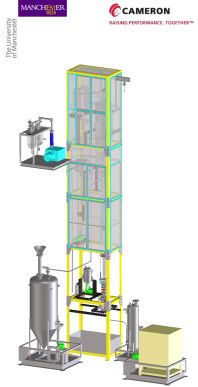

Monika has started her higher education at Poznan University of Technology, Poland, in the Process Engineering Department. After her 4 years of studies she has been awarded studentship for "knowledgeable students" to continue her MSc studies at Aalborg University Esbjerg. The scholarship was awarded by Danish Government and Babcock & Wilcox Vølund Company, which was a collaborator of each project during the Masters course. The projects topics stretched from waste impacts analysis, modelling of burning piece of coal in the incineration chamber of Babcock & Wilcox Vølund, to incineration bottom ash studies. After the Masters studies Monika has undertaken the PhD course in crystallisation processes at Manchester University, CEAS, UK, in collaboration with Cambridge Crystallographic Data Centre and under supervision of world famous Prof. Roger Davey. The PhD thesis was titled: "A combined experimental and Cambridge Structural Database (CSD) study of crystalline solvates". Currently, Monika is a Research Associate in the Multiphase Processing Group under the supervision of Dr. Peter Martin at the University of Manchester, UK in CEAS. The project focuses on the problems arising from reclamation of monoethylene glycol used to prevent hydrate formation in long sub-sea pipelines, in oil and gas industry. As the hydrates are mineral-scaling it is important to prevent their formation and insure the protection of pipelines' surfaces and oil and gas transport efficiency. Having the compact and efficient MEG reclamation unit at the sea would help to improve economics and environmental aspects of hydrates removal. The experimental part of the project is conducted on the three stories MEG reclamation pilot plant based in the Morton Laboratory. This project involves active collaboration and knowledge transfer between Cameron Systems Ltd. and The University of Manchester. The duration of the project is 3 years.

| |

|

|