Introduction

Problems

of fluid transport through stochastic porous media arise in diverse applications

from medicine, the oil industry, air conditioning, fluid separation, battery

separator and sundry other contexts where permeable membranes are employed.

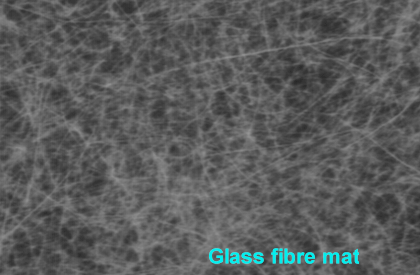

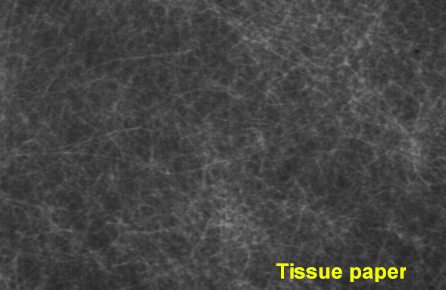

The most common

types of materials used in all of the above are nonwoven fabrics, ranging

from synthetic textiles and paper to thick glass fibre mats; all of these

are made by a fluid-laid stochastic process that deposits fibres into an evolving

pad as it develops structural rigidity. Here, the manufacturing process itself

is an evolving stochastic fluid flow as the pad grows by a stochastic filtering

mechanism. In other cases a complex transfer material may be a stochastically

porous plug or baffle region as an element in a deterministic flow system

and then we represent it by an appropriately coupled stack of porous strata.

We have a general

analytic model (cf References below) for the structural variability in such

stochastic porous media and we have an analytic solution for the statistical

features of transport of fluids through the media, under all types of flow

regimes: laminar, capillary, turbulent and molecular. We can accommodate also

the situation of progressive occlusion of pores by filtrate or the opposite

mechanism of back-washing.

The Stochastic

Flow Simulator (SFS) allows the deployment of our analytic results

to generate numerical values for spatial structural statistics and flow statistics,

which can then illustrate graphically the context and state of flow of any

chosen conditions of stochastic porous media and flow type.

In particular,

this software can be used to highlight the likelihood of extreme values in

evolving structure or to project end-usage flow behaviour under arbitrary

conditions.

Such monitoring

information in the form of graphics and animations can be absorbed at a glance

by the operator or process control engineer, for example when synthesized

from on-line data and refreshed in real time during manufacture or converting

operations. It can be used also in the design of new materials. We give below

some summaries of case studies and provide some illustrative animations.

SFS:

The Stochastic Flow Simulator

Functionality

The SFS

provides a representation of the spatial statistics of the pore size distribution

in a horizontal slice of an arbitrary stochastic porous medium. It does this

using computations in a large array of finite zones, to generate the local open

area distribution and then computes the local flow rate distribution, for arbitrary

flow modes---laminar, turbulent, capillary or molecular. These models allow

stacking of multilayer slabs of stochastic porous media of arbitrary porosity

and spatial variability.

Applicability

Such information

could be provided for on-line monitoring of the product quality in continuous

manufacturing processes for filter media of nonwoven or paper type. In applications

to flow processes, computations from our models can provide graphical animations

at any scale to assist operators in achieving rapid appreciation of the process

state and its evolution. So, control engineers could use raw on-line manufacturing

data to generate end-user behaviour and properties in arbitrary flow processes.

Quality Control

Off-line, in the

lab, SFS can use quality control data for a sample of the stochastic

medium to generate spatial statistics for the structure and for any desired

mechanism of fluid transport through it.

In practice,

the parameters for nonwoven filter fabrics can be derived from our analytic

procedures applied to optical or radiographic transmission images.

Geological

In the field, for

large-scale stochastic porous media, such as aggregate beds or sand-shale-rock

environments encountered in water and oil extraction, geophysical magnetometry

methods would be appropriate. Then SFS could allow estimation of flow

rates and variability.

Medical

At the other extreme,

the recovery of the human body from burns, trauma damage or surgery, involves

the growth of fibrin fibres in a more or less anisotropic rather haphazard array.

The evolving stochastic fibrous fibrin network is at the front line in defence

against infection and loss of body fluids, so its transport properties and their

evolution during healing need to be monitored and and SFS simulations

could allow projection of recovery patterns and the scheduling of continuing

treatment.

Demonstration

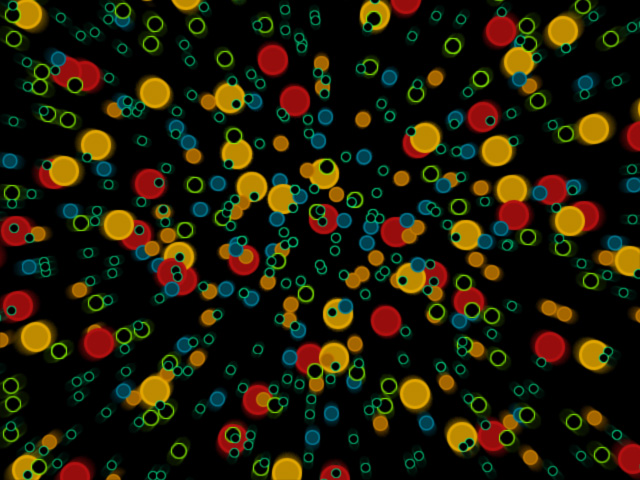

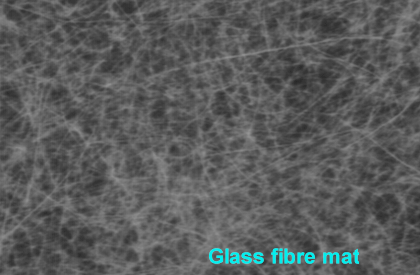

Distributions

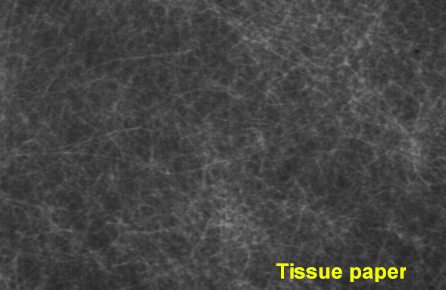

in this set of small-scale demonstration graphics are set to unit mean and are

typical of the properties of stochastic porous filter-type barrier or separator

materials such as non-woven textiles, glass mats and paper. For such materials

the pore size distributions can be estimated by image analysis of radiographs

or micrographs, or from the statistics of mean flow rate growth with applied

pressure drop increase. Here are radiographs of two samples:

The animations

below show representative spatial distributions of the local pore radii and

local flow rate; other features can be represented similarly.

Colour codings for quartiles 1 to 4: blue, green, orange, red.

Local mean pore radii

Local mean pore radii

Local

mean flow rate

Local

mean flow rate

Contact the authors for

more information:

References

-

Modeling a class of stochastic porous media.

C.T.J. Dodson and W.W. Sampson. App. Math. Lett. 10, 2 (1997) 87-89.

-

Spatial statistics of stochastic fibre networks.

C.T.J. Dodson and W.W. Sampson. J. Statist. Phys. 96, 1/2 (1999) 447-458.

-

Flow simulation in stochastic porous media.

C.T.J. Dodson and W.W. Sampson. Simulation, 74:6, (2000) 351-358.

-

Bivariate normal thickness-density structure in real near-planar stochastic

fibre networks.

C.T.J. Dodson and W.W. Sampson. J. Statist. Phys. 102, 1,2, (2001)

345-353.

-

On the distributions of mass, thickness and density of paper.

C.T.J. Dodson, Y. Oba and W.W. Sampson. Appita J. 54, 4 (2001) 385-389.

-

On the distribution of pore heights in layered random

fibre networks.

C.T.J. Dodson, Proc. 11th Fundamental Research Symposium,

Oxford, 17-21 September 2001, (2001) pp 1037-1042.

design:

chrisdod@blueyonder.co.uk

![]()

![]()

Local mean pore radii

Local mean pore radii

Local

mean flow rate

Local

mean flow rate