Nanometre-Scale Patterning

Conventional semiconductor devices are made using the so-called photo-lithography. The resolution is typically 1 micron, limited by the wavelength of the UV light used. To create nanometre-scale structures, electron beams have been used to replace UV light in the so-called electron-beam lithography. The electrons are accelerated by a very high voltage, typically tens of kV, and then focused onto a layer of polymer to create very fine patterns. Among the disadvantages is however one cannot inspect the sample after the lithography to see if the pattern has been created successfully. Otherwise, the high-energy electron beam could damage the semiconductor.

Over the recent years, scanning probe microscope (SPM)-based nanotechnology has become a

very promising and competitive alternative to the electron-beam lithography.

SPM-based lithography consists two

approaches, mechanical and electrochemical. The mechanical approach is to use

the probe to plough or to perform probe indentation (tip oscillating) on the

surface of a thin layer of polymer on a semiconductor sample, in a very

accurate and well-controllable manner. Subsequent etch, for example, will be

carried out to transfer the nanometre-pattern to the semiconductor. The

electrochemical approach, based on local anodic oxidation (LAO), has become the

most popular method, in which the probe is negatively biased to impose a huge

local electric field of about 109 V/m and

hence induce a localized oxide beneath the probe. The oxidised areas typically

have an increased volume, and can be imaged conveniently using the AFM

immediately after the oxidation.

Our advanced CP-R SPM system has been a great tool for us to develop new types of semiconductor device concepts. Below are images showing the atomic resolution of our SPM and some of the patterns created.

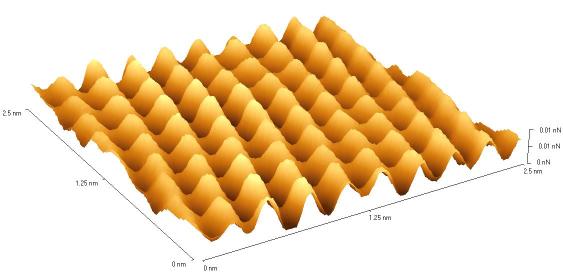

|

An image showing individual atoms on a crystal lattice, taken by our atomic force microscope (AFM). The area is 2.5 nm by 2.5 nm. |

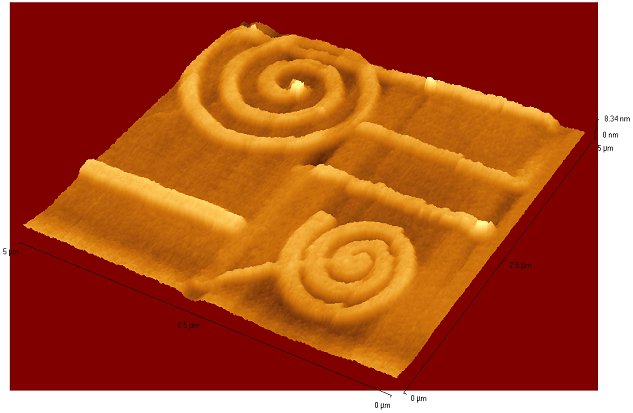

|

Spirals and lines created with our SPM on doped silicon substrate. |

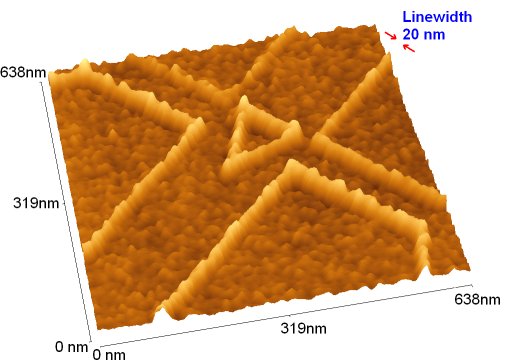

|

Pattern of a nanometre-scale ballistic rectifier created by anodic local oxidation. The Ti metal grains can also be clearly seen in the background.

|

|

The UMIST logo shown here was made by our AFM recently on a piece of silicon. It is actually thousands times smaller than it appears!

|