J. D. Jackson

Reynolds the Engineer

Osborne Reynolds had developed an interest in problems connected with

the dynamics of ships, particularly screw steamers, a number of years

prior to coming to Manchester, probably dating back to his

apprenticeship with Edward Hayes at Stony Stratford. This further

parallel stream of research led to publications in the Transactions of

the Institution of Naval Architects and later to a long involvement in

work concerned with the safety of ships. Much of the work was carried

out under the auspices of a specially formed committee of the British

Association for the Advancement of Science which included, amongst

others, Kelvin, Froude and Rayleigh, and for which Reynolds produced a

series of important lengthy reports. His attention later turned to

waves and currents and the laws relating the scaling of experiments to

study flow in rivers, estuaries and foreshores. A further series of

reports for the British Association followed.

Back to Contents

The first fruits of the interest in ships inculcated at Stony Stratford

were his publications in 1873 and 1874 on the racing of screw propellers

(Papers 9 and 14). By showing this to be the result of the admission of

air Reynolds was among the first to recognize the important influence

which air can exert on a mass of water in which it is dissolved or

occluded. From his studies, he deduced that it is more important to

ensure that a propeller is sufficiently submerged than to increase its

diameter and that it seemed likely that some of the advantage of twin

screws was derived from their depth of immersion being generally greater

than that for a single screw.

The conclusions which he reached later concerning the racing of screws

and the steering of screw-steamers, Paper 19 (1875), were largely based

on pioneering experiments made with two models, one 2 feet 6 inches long

driven by a spring and the other 5 feet 6 inches, driven by steam. He

contended that

`the reversing of the screw of a vessel with full way on very much

diminishes her steering-power,... so that where a collision is imminent,

to reverse the screw and use the rudder as if the ship would answer to

it in the usual manner is a certain way of bringing about the collision'.

His model experiments indicated, moreover, that the influence of

reversing the screw to turn the vessel independently of her rudder was

most pronounced when the screw was not deeply submerged.

Reynolds went so far as to suggest, Paper 26 (1876), that models in the

form of steam- launches should be used for training naval officers in

the manoeuvring of ships. This proposal was not adopted, but Reynolds'

views had aroused so much interest and concern that the British

Association appointed a committee, with Reynolds as Secretary, to

collect and examine evidence concerning the steering qualities of

steamships. In addition to having tests made on actual ships, the

Committee received reports from ships' masters who had carried out

similar experiments on their own merchant vessels. Reynolds produced

three detailed reports for the Committee on this work (

Papers 28, 32 and 37). In their 1878 Report, the British

Association Committee affirmed that `the conclusions drawn by Professor

Reynolds from experiments on models have been fully confirmed by the

experiments on full-sized ships'.

Reynolds returned to the subject of ship-models some years later after a

disaster had occurred with the St. Annes and Southport lifeboats.

Within a week of this tragic occurrence, he read his paper `On Methods

of Investigating the Qualities of Lifeboats' to the Manchester Literary

and Philosophical Society, Paper 54 (1886), in which he urged that

scale-models should be used to test the sea-going qualities of lifeboats.

Back to Contents

From the dynamics of ships we turn next to the development of hydraulic

machinery and in particular pumps and turbines. In matters of

innovation and invention Reynolds was never motivated by financial gain

and it is doubtful whether he ever had any monetary reward from any of

his inventions. He did, however, take out a number of patents. These

are listed in the appendix to this paper. The patent for `improvements

in turbines and centrifugal pumps', the specification for which is dated

1875, is reprinted as Paper 20 in Volume I of the Collected Works. It

reads, in many respects, like a research-paper and at the same time

demonstrates Reynolds' great powers as an engineer and inventor.

His proposal envisaged the use of a succession of stages, such that:

`on emerging from the moving passages the fluid shall not, as in the

case of the ordinary turbine, have spent the whole or nearly the whole

of its available pressure, but that it shall still have sufficient

pressure to carry it through one or more additional sets of passages...

that is to say, on emerging from the first moving passages, it shall

again be received into other fixed passages, so that on being forced

through them it shall emerge with a velocity of whirl or rotary motion

round an axis - not necessarily the same as before - with a reduced

pressure, and again be received into another set of moving passages from

which it may emerge with no velocity of whirl... On emerging from the

last set of passages the fluid will be allowed to flow away into such

receptacle, channel or tail-race as may be provided'.

Reynolds describes how these sets of passages may be arranged side by

side as in a parallel (axial) flow turbine or one set within the other

in radial fashion. Figure 13 is taken from his specification which goes

on to state that the inverse arrangement could serve as a multi-stage

centrifugal pump and that the invention `applies to all fluids, liquids,

vapours and gases.' He further incorporated the idea of guide-vanes and

divergent passages surrounding the impeller of a centrifugal pump for

the improved recovery of dynamic head and the concept of movable

guide-vanes for regulating the inflow to water turbines.

Reynolds describes how these sets of passages may be arranged side by

side as in a parallel (axial) flow turbine or one set within the other

in radial fashion. Figure 13 is taken from his specification which goes

on to state that the inverse arrangement could serve as a multi-stage

centrifugal pump and that the invention `applies to all fluids, liquids,

vapours and gases.' He further incorporated the idea of guide-vanes and

divergent passages surrounding the impeller of a centrifugal pump for

the improved recovery of dynamic head and the concept of movable

guide-vanes for regulating the inflow to water turbines.

The first multi-stage, or `turbine pump' as it is rather ambiguously

described, was successfully installed in Reynolds' own laboratories.

Prototypes of his pumps and turbines are on display in the exhibition

referred to earlier.

A.H. Gibson [6] has pointed out that

in his 1875 patent specification, Reynolds anticipated both the

multi-stage turbine of the Parsons type and the turbine with opposite

rotation of the two elements as in the Ljungstrom turbine. About this

time (1875-76), Reynolds did in fact experiment with a two-stage small

radial-flow steam turbine with a wheel- diameter of 6 inches which ran at

12,000 revolutions per minute. While it worked successfully, its

consumption of steam was high, probably because of relatively large

losses between the blades and the casing.

Back to Contents

1887 marked another of Reynolds pre-eminent contributions. In that year

he addressed the Manchester meeting of the British Association `On

Certain Laws Relating to the R‚gime of Rivers and Estuaries, and on the

Possibility of Experiments on a Small Scale' (Paper 55).

Reynolds' first scale model was of the Mersey and covered the region

between Liverpool Narrows and a point some distance below Runcorn; it

had a flat bed and vertical sides representing the shape of the estuary

at high tide; the horizontal scale was 2 inches to a mile (1/31800) and

the vertical scale 1 inch to 80 feet (1/960), giving a vertical

exaggeration of approximately 33:1. Tides were generated by a hinged

tray at the seaward side of the model. Reynolds noticed that only one

period - about 40 seconds - gave a correct imitation of the tidal

phenomena in the actual Mersey: `a result', he says,

`that might have been foreseen from the theory of wave motions, since

the scale of velocities varies as the square roots of the scales of wave

heights, so that the velocities in the model which would correspond to

the velocities in the channel would be as the square roots of the

vertical scales ... and the ratios of the periods would be the ratio of

horizontal scales divided by this ratio of velocities.'

Reynolds had, therefore, established the rule that if the horizontal

scale is 1/x and the vertical scale is 1/y, the logical corollary is

that the velocity-scale should be 1/ûy and the time- scale for tidal

periods ûy/x. This was a major advance and opened up great

possibilities for modelling flow in rivers and estuaries.

In addition Reynolds astutely observed that his tide-generator also

accurately shaped the sand he had placed in the model (to ensure the

correct mean depth of water at high tide) to mirror the principal

features of the natural estuary.

As a direct consequence of this he produced a larger version with a

horizontal scale of 6 inches to a mile (1/10560) and a vertical scale of

one inch to 33 feet (1/396) which underwent 6,000 tides. This model he

showed to the British Association alongside charts of the real estuary

and invited fellow members to note the `remarkable resemblance in the

general features to the charts of the Mersey.' Reynolds went on:

`From my present experience in constructing another model, I should

adopt a somewhat greater exaggeration of the vertical scale. In the

meantime I have called attention to these results, because this method

of experimenting seems to afford a ready means of investigating and

determining beforehand the effects of any proposed estuary or harbour

works; a means which, after what I have seen, I should feel it madness

to neglect before entering upon any costly undertaking.'

So strong was the evidence presented by Reynolds that the British

Association immediately acted to establish a committee to investigate

the action of waves and currents on the beds and foreshores of estuaries

by means of working models. The research was planned and carried out by

Reynolds in the Whitworth Engineering Laboratory at Owens College, and

three Reports were issued, Papers 57, 58 and 59 (1889,

1890, 1891).

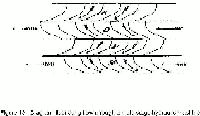

These were written by Reynolds himself and described in great detail the

experiments made on model estuaries of hypothetical shape: rectangular,

V-shaped, and V-shaped with straight tidal rivers added at the upper

ends. Figure 14 gives some idea of the bed formation and other features

of one of these models.

So strong was the evidence presented by Reynolds that the British

Association immediately acted to establish a committee to investigate

the action of waves and currents on the beds and foreshores of estuaries

by means of working models. The research was planned and carried out by

Reynolds in the Whitworth Engineering Laboratory at Owens College, and

three Reports were issued, Papers 57, 58 and 59 (1889,

1890, 1891).

These were written by Reynolds himself and described in great detail the

experiments made on model estuaries of hypothetical shape: rectangular,

V-shaped, and V-shaped with straight tidal rivers added at the upper

ends. Figure 14 gives some idea of the bed formation and other features

of one of these models.

Back to Contents

To conclude this review of Reynolds' work on hydraulics we come to a

short paper presented at a meeting of the British Association at Oxford

entitled `Experiments concerned with the boiling of water in an open

tube at ordinary temperatures', Paper 63 (1894). The paper begins with

a description of the processes involved in the boiling of water by

heating it. However, it is really about the phenomenon of cavitation, a

common problem in hydraulic machinery involving the production of vapour

bubbles in flowing water as a result of the pressure being reduced

locally to the point where nucleation occurs.

In experiments exhibited at the meeting he used a glass tube of internal

diameter half an inch and length six inches drawn down to a neck in the

middle, something less than a tenth of an inch bore. Coupling one end

of this to the water main and inclining the open end downwards into a

vessel filled with water (see Figure 15), he proceeded to turn on the

water very slowly so as to fill the tube, then increased the flow until

at a particular velocity a distinct sharp hiss was heard. Reynolds

described the situation thus:

In experiments exhibited at the meeting he used a glass tube of internal

diameter half an inch and length six inches drawn down to a neck in the

middle, something less than a tenth of an inch bore. Coupling one end

of this to the water main and inclining the open end downwards into a

vessel filled with water (see Figure 15), he proceeded to turn on the

water very slowly so as to fill the tube, then increased the flow until

at a particular velocity a distinct sharp hiss was heard. Reynolds

described the situation thus:

`as the bubbles of air and vapour would be carried with great velocity

from the low pressure at the neck, where they formed, into the higher

pressure in the wider portion of the expanding tube; so that the

pressure being greater than the vapour tension, condensation would ensue

and the bubbles would collapse...'

Nowhere in the paper does Reynolds use the word `cavitation', yet both

here and in his investigation of the racing of screw propellers, he was

patently demonstrating his understanding of it.

Back to Contents

This area of work interested Osborne Reynolds throughout his career.

There can be no doubt that the presence in Manchester of the eminent

scientist Joule was an important influence at the outset. To this can

be added the influence of Rankine, whose texts Reynolds frequently

referred to.

Reynolds' early contributions on the effect of air on the rate of

condensation of steam at a surface and on the extent and action of

heating surfaces for steam boilers were followed after a gap of about

ten years by detailed studies on the steam engine indicator and trials

on a large triple expansion steam engine, culminating in 1897 in a

classical experiment using that equipment to determine the mechanical

equivalent of heat. The later studies highlight Reynolds' outstanding

practical ability and his interest in experimentation using full scale

engineering plant. His papers are to be found in both Volumes I and II

of the Collected Works. Some were published by the Institution of Civil

Engineers and others by the Royal Society.

Back to Contents

In Paper 10 (1873) Reynolds states that he was interested to discover

`how far the presence of a small quantity of air affects the power of a

cold surface to condense steam.' The means by which he did so were

characteristically simple. The equipment consisted of a glass flask in

which a `surface condenser' took the form of a copper pipe passing in

and out of the cork. Water was forced through the pipe to keep it cool.

From experiments using this apparatus Reynolds deduced that, while there

is no limit to the rate at which pure steam will condense but the power

of the surface to carry off the heat, the rate of condensation

diminishes rapidly as the quantity of air present increases. He

concludes:

`that in consequence of this effect of air it is necessary for the size

of a surface- condenser for a steam-engine to increase very rapidly with

the quantity of air allowed to be present within it; ... and that by

mixing air with the steam before it is used, the condensation at the

surface of a cylinder may be greatly diminished, and consequently the

efficiency of the engine increased'.

Back to Contents

In 1874 (some nine years before the appearance of the famous paper on

laminar and turbulent flow) Reynolds produced a short and farsighted

paper, `On the extent and action of the heating surface of steam

boilers', in which he pointed out that heat is removed from such a

surface not only through molecular action but also by the turbulent

eddies present in the flow which mix hotter fluid with cooler fluid.

He argued and demonstrated experimentally that if hot gas flowed at

sufficiently high speed through a tube, the temperature of which was

maintained constant, the temperature of the gas emerging from the end of

the tube would be sensibly independent of any further increase of speed.

This effect he related to the fact that under such conditions the

resistance to flow is sensibly proportional to the square of the

velocity, thereby inferring an analogy between heat-transfer and

skin-friction. Almost half a century was to pass before these ideas

were taken up and the analogy extended by later authorities such as

Taylor, Prandtl and von Karman.

Back to Contents

In an address entitled `On the general theory of thermo-dynamics'

delivered to the Institution of Civil Engineers in November 1883

(Paper 47), Reynolds began by amusingly acknowledging the challenge he

faced:

`In lecturing on any subject, it seems to be a natural course to begin

with a clear explanation of the nature, purpose, and scope of the

subject. But in answer to the question "What is thermo-dynamics?" I

feel tempted to reply "It is a very difficult subject, nearly, if not

quite, unfit for a lecture".'

Reynolds then proceeded to describe what he saw as the real difficulty in the

appreciation of thermo-dynamics:

`It deals with a thing or entity (if I may so call heat) which, although

we can recognise and measure its effects, is yet of such a nature that

we cannot with any of our senses perceive its mode of operation.'

To assist his audience in understanding the ideas involved he went on

later to use a simple mechanical contrivance to demonstrate the problem

of converting heat into work. It is indicative of his approach that not

a single equation or even a mathematical symbol appears anywhere in his

paper.

Back to Contents

In a paper read before the Manchester Literary and Philosophical Society

in November 1885 (Paper 53), Reynolds considered the thermodynamics of

fluid flow in the case of a gas or vapour discharging from one vessel

into another through an orifice or nozzle. He called attention to the

fallacy of the assumption that the pressure in the receiving vessel is

the same as that at the orifice, and went on to consider the observation

that the rate of flow was only affected by the pressure in the receiver

if that were greater than about half of the pressure in the upstream

vessel. Moreover, he established that the reason for this lay in the

fact that a limit to the flow is reached when the velocity at the

orifice becomes equal to the velocity of sound at that point.

Back to Contents

In Paper 56 read to the Institution of Civil Engineers in December 1889,

Reynolds described with some pride the large triple-expansion steam

engine which had been installed under his close supervision in the

Whitworth Engineering Laboratory at Owens College (see Figure 16).

Characteristically, Reynolds ensured that this new test facility was

extremely flexible. The engine could be operated as a

triple-expansion condensing engine or run in a variety of other ways.

In Paper 56 read to the Institution of Civil Engineers in December 1889,

Reynolds described with some pride the large triple-expansion steam

engine which had been installed under his close supervision in the

Whitworth Engineering Laboratory at Owens College (see Figure 16).

Characteristically, Reynolds ensured that this new test facility was

extremely flexible. The engine could be operated as a

triple-expansion condensing engine or run in a variety of other ways.

In his address he defined the purpose of the engines as two-fold; (i) to

afford students practice in making the many measurements involved in

steam engine-trials, to give them an insight into the action of the

steam and the mechanical components and to familiarize them with good

design; (ii) to supply a means of research by which the knowledge of the

steam- engine could be extended.

The detailed design and the construction of the engines and the boiler

were undertaken by Messrs. Mather and Platt, whose `zeal and liberality'

Reynolds gratefully acknowledged. It was decided to have the three

engines on separate brakes and that these should be hydraulic devices

rather than ones dependent on mechanical friction.

William Froude had earlier developed a radically new design for a

compact hydraulic brake for determining the power of large engines.

Accordingly, Reynolds tested a 4-inch diameter model of the new design.

He found that when the speed exceeded a certain limit, the brake

partially emptied itself of water and the resistance correspondingly

decreased. To overcome this defect, Reynolds had radial holes drilled

through the metal of the fixed vanes in such a way as to maintain the

water in the brake at atmospheric pressure or above it under all

conditions of operation. Having tested this idea out using his model,

Reynolds adopted it successfully on the 18-inch wheels which became the

hydraulic brakes for his three-cylinder steam engine. The dynamometer

is illustrated in Figure 17.

William Froude had earlier developed a radically new design for a

compact hydraulic brake for determining the power of large engines.

Accordingly, Reynolds tested a 4-inch diameter model of the new design.

He found that when the speed exceeded a certain limit, the brake

partially emptied itself of water and the resistance correspondingly

decreased. To overcome this defect, Reynolds had radial holes drilled

through the metal of the fixed vanes in such a way as to maintain the

water in the brake at atmospheric pressure or above it under all

conditions of operation. Having tested this idea out using his model,

Reynolds adopted it successfully on the 18-inch wheels which became the

hydraulic brakes for his three-cylinder steam engine. The dynamometer

is illustrated in Figure 17.

Back to Contents

As a result of these efforts Reynolds had brought into being a

large-scale apparatus suitable for the most accurate determination yet

of Joule's mechanical equivalent of heat. Reynolds recognised that the

attraction lay not only in the magnitude of the quantities to be

measured but also in the possibility of using two physically fixed

points of temperature by measuring the quantity of work required to heat

a known mass of water from freezing point to boiling point. This could

be achieved by feeding water continuously at freezing temperature to the

brake in which the internal fluid friction would heat it to boiling

point.

This classic investigation was described in great detail in

Paper 66,

the Bakerian Lecture to the Royal Society in May 1897. The apparatus is

shown in Plate 1. Plate 2 shows the brake and some associated

equipment. One of the striking features of the study is the thorough

consideration given to the circumstances which might affect the accuracy

of the results. Twenty-five possible sources of error are tabulated,

together with an assessment of the limits of relative errors to which

they could give rise.

This classic investigation was described in great detail in

Paper 66,

the Bakerian Lecture to the Royal Society in May 1897. The apparatus is

shown in Plate 1. Plate 2 shows the brake and some associated

equipment. One of the striking features of the study is the thorough

consideration given to the circumstances which might affect the accuracy

of the results. Twenty-five possible sources of error are tabulated,

together with an assessment of the limits of relative errors to which

they could give rise.

Five years earlier, in 1892, Reynolds had produced a brilliant biography

for the Manchester Literary and Philosophical Society simply entitled

`Memoir of James Prescott Joule' [7], but

his re-determination of the mechanical equivalent of heat perhaps

represented the ultimate tribute Reynolds was able to pay to him.

Five years earlier, in 1892, Reynolds had produced a brilliant biography

for the Manchester Literary and Philosophical Society simply entitled

`Memoir of James Prescott Joule' [7], but

his re-determination of the mechanical equivalent of heat perhaps

represented the ultimate tribute Reynolds was able to pay to him.

Back to Contents

This lesser known side of Reynolds' work encompassed a wide variety o

f topics mainly of a rather practical nature. These include: elasticity

and fracture; properties of steel; stress concentration; inertial forces

and stresses; friction; slipping of belts and straps; rolling friction;

vibration measurement; and last but not least, the fatigue of materials

subjected to repeated loading. We do not have to look far to detect the

incentive for such work. In the city of Manchester Reynolds was

surrounded by intensive mechanical engineering activity with all its

attendant problems.

A number of his papers on these themes were published in The Engineer.

His pioneering work on rolling friction was presented to the Royal

Society as was his collaborative work on repeated stresses and fatigue.

Back to Contents

In Paper 17 `On the efficiency of belts or straps as communicators of

work' (1874), Reynolds explained the slipping of the strap used for a

belt-drive between two pulleys. The elasticity of the belt caused the

tight side to be stretched more than the slacker side and

correspondingly the tight side had to move faster. Some months later,

in the Philosophical Transactions of the Royal Society,

Paper 18 (1875),

he extended this concept to a detailed study of rolling friction,

arguing and demonstrating experimentally that, as in the case of endless

belts over pulleys, there would be an `analogous slipping when a hard

roller rolls on a soft surface, or when an india-rubber wheel rolls on a

hard surface'. He found that `an iron roller rolled through something

like three-quarters of an inch less in a yard when rolling on

india-rubber than when rolling on wood or iron'. He proceeded to show

that, whatever the nature of the materials, the deformation at the point

of contact must cause slipping to occur, even though this would be

difficult to measure with hard materials. In this way, he accounted for

the resistance to the motion of a roller, and further explained the

disquieting phenomenon of the scaling of wrought-iron railway rails as

being a consequence of the slipping which attends the rolling.

Back to Contents

Reynolds' four articles in The Engineer (1881-82) on the `Fundamental

Limits to Speed' (Paper 41) remind us that what is common knowledge

today was not at all clearly understood before he expounded it. He

defines one limit to possible speeds as the limited strength of

materials in relation to their weight, but also points to the fact that

the properties of materials are essentially restricted in other

respects, for example by the limited temperature at which a material

retains its strength. He then goes on to deal with dynamic effects and

stresses arising from acceleration and to consider the problem of

vibrations and the periodic forces set up by the reciprocation of moving

parts. This in turn leads him to call attention to the danger which

arises if these forces synchronise with the natural period of

oscillation of the whole or of a part of the structure. Reynolds

concludes by reflecting on the possibility of balancing the whole or a

portion of the moving masses in a locomotive and points out that, while

the revolving parts may be completely balanced, it is impossible to

achieve complete balance of the oscillating masses.

Back to Contents

Although not included among the Collected Papers, an investigation of

the fatigue of materials subjected to repeated stresses deserves notice

as a contribution of some significance. The research was conceived by

Reynolds and carried out in his laboratories. It is described in a

paper with J.H. Smith published in the Philosophical Transactions of the

Royal Society in 1902 [8].

.

Back to Contents

- 6. Gibson, A.H. 1946 Osborne Reynolds and his work

in hydraulics and hydrodynamics. published by

Longmans Green, for the British Council.

Back

- 7. Reynolds, O. 1892 Memoir of James Prescott Joule.

Mem. and Proc., Manch. Lit. and Phil. Soc., 4th

Series, vol. 6. Back

- 8. Reynolds, O. and Smith J.H. 1902 On a

throw-testing machine for reversals of mean stress.

Phil. Trans. Roy. Soc., Ser. A., vol. 199, p 265.

Paper 9 `The causes of the racing of the engines of screw steamers

investigated theoretically and by experiment'. Institution of

Naval Architects, Trans., 1873. Back

Paper 10 `On the condensation of a mixture of air and steam upon cold

surfaces'. Royal Society, Proceedings, No. 144, 1873.

Back

Paper 14 `On the extent and action of the heating surface of steam boilers'.

Manchester Literary and Philosophical Society, Proceedings, Vol.

14, Session 1874-5. Back

Paper 17 `On the efficiency of belts or straps as communicators of work'.

The Engineer, Nov. 27, 1874. Back

Paper 18 `On rolling friction'. Royal Society, Phil. Trans., Vol. 166, Pt. 1.

Back

Paper 19 `On the steering of screw-steamers'. British Association Report,

1875. Back

Paper 20 `Improvements in turbines and centrifugal pumps'. Specification of

Patent No. 724, 1875. Back

Paper 26 `On the investigation of the steering qualities of ships'. British

Association Report, 1876. Back

Paper 28 `On the effect of propellers on the steering of vessels'. British

Association Report, 1877. Back

Paper 32 `On the steering of screw steamers'. Report of the Committee,

consisting of James R. Napier, F.R.S., Sir W. Thomson, F.R.S.,

J.T. Bottomley and Osborne Reynolds, F.R.S. (Secretary), appointed

to investigate the effect of Propellers on the Steering of Vessels.

British Association Report, 1878. Back

Paper 37 `On the steering of ships'. British Association Report, 1880.

Back

Paper 41 `On the fundamental limits to speed' I, II, III and IV. The

Engineer, Oct. 28, 1881; Nov. 18, 1881; Dec. 9, 1881; March 17,

1882. Back

Paper 47 `On the general theory of thermo-dynamics'. Institution of Civil

Engineers, Proceedings, November 15, 1883. Back

Paper 53 `On the flow of gases', Philosophical Magazine, March 1886.

Back

Paper 54 `On methods of investigating the qualities of lifeboats'.

Manchester Literary and Philosophical Society, Proceedings, Vol.

26, Session 1886-87. Back

Paper 55 `On certain laws relating to the regime of rivers and estuaries,

and on the possibility of experiments on a small scale'. British

Association Report, 1887. Back

Paper 56 `On the triple-expansion engines and engine-trials at the Whitworth

Engineering Laboratory, Owens College, Manchester'. Institution

of Civil Engineers, Proceedings, 1889-90. Back

Paper 57 `Report of the committee appointed to investigate the action of

waves and currents on the beds and foreshores of estuaries by

means of working models'. British Association Report, 1889.

Back

Paper 58 `Second report of the committee appointed to investigate the action

of waves and currents on the beds and foreshores of estuaries by

means of working models'. British Association Report, 1890.

Back

Paper 59 `Third report of the committee appointed to investigate the action

of waves and currents on the beds and foreshores of estuaries by

means of working models'. British Association Report, 1891.

Back

Paper 63 `Experiments showing the boiling of water in an open tube at

ordinary temperatures'. British Association, Section A, 1894.

Back

Paper 66 `Bakerian Lecture - On the mechanical equivalent of heat'. Joint

paper with W.H. Moorby. Royal Society, Phil. Trans., London, 1897.

Back

Back to Contents

Document written by

Prof. J.D. Jackson

Centre for the History of Science, Technology & Medicine

Faculty of Life Sciences

University of Manchester, Manchester M13 9PL

e-mail: jdjackson@manchester.ac.uk

Web Pages prepared by Dr. J. E. Byrne

Back to Contents ||

Back to Main Document ||

Reynolds the Scientist ||

In experiments exhibited at the meeting he used a glass tube of internal

diameter half an inch and length six inches drawn down to a neck in the

middle, something less than a tenth of an inch bore. Coupling one end

of this to the water main and inclining the open end downwards into a

vessel filled with water (see Figure 15), he proceeded to turn on the

water very slowly so as to fill the tube, then increased the flow until

at a particular velocity a distinct sharp hiss was heard. Reynolds

described the situation thus:

In experiments exhibited at the meeting he used a glass tube of internal

diameter half an inch and length six inches drawn down to a neck in the

middle, something less than a tenth of an inch bore. Coupling one end

of this to the water main and inclining the open end downwards into a

vessel filled with water (see Figure 15), he proceeded to turn on the

water very slowly so as to fill the tube, then increased the flow until

at a particular velocity a distinct sharp hiss was heard. Reynolds

described the situation thus:

Reynolds describes how these sets of passages may be arranged side by

side as in a parallel (axial) flow turbine or one set within the other

in radial fashion. Figure 13 is taken from his specification which goes

on to state that the inverse arrangement could serve as a multi-stage

centrifugal pump and that the invention `applies to all fluids, liquids,

vapours and gases.' He further incorporated the idea of guide-vanes and

divergent passages surrounding the impeller of a centrifugal pump for

the improved recovery of dynamic head and the concept of movable

guide-vanes for regulating the inflow to water turbines.

Reynolds describes how these sets of passages may be arranged side by

side as in a parallel (axial) flow turbine or one set within the other

in radial fashion. Figure 13 is taken from his specification which goes

on to state that the inverse arrangement could serve as a multi-stage

centrifugal pump and that the invention `applies to all fluids, liquids,

vapours and gases.' He further incorporated the idea of guide-vanes and

divergent passages surrounding the impeller of a centrifugal pump for

the improved recovery of dynamic head and the concept of movable

guide-vanes for regulating the inflow to water turbines.

So strong was the evidence presented by Reynolds that the British

Association immediately acted to establish a committee to investigate

the action of waves and currents on the beds and foreshores of estuaries

by means of working models. The research was planned and carried out by

Reynolds in the Whitworth Engineering Laboratory at Owens College, and

three Reports were issued, Papers 57, 58 and 59 (1889,

1890, 1891).

These were written by Reynolds himself and described in great detail the

experiments made on model estuaries of hypothetical shape: rectangular,

V-shaped, and V-shaped with straight tidal rivers added at the upper

ends. Figure 14 gives some idea of the bed formation and other features

of one of these models.

So strong was the evidence presented by Reynolds that the British

Association immediately acted to establish a committee to investigate

the action of waves and currents on the beds and foreshores of estuaries

by means of working models. The research was planned and carried out by

Reynolds in the Whitworth Engineering Laboratory at Owens College, and

three Reports were issued, Papers 57, 58 and 59 (1889,

1890, 1891).

These were written by Reynolds himself and described in great detail the

experiments made on model estuaries of hypothetical shape: rectangular,

V-shaped, and V-shaped with straight tidal rivers added at the upper

ends. Figure 14 gives some idea of the bed formation and other features

of one of these models.

In Paper 56 read to the Institution of Civil Engineers in December 1889,

Reynolds described with some pride the large triple-expansion steam

engine which had been installed under his close supervision in the

Whitworth Engineering Laboratory at Owens College (see Figure 16).

Characteristically, Reynolds ensured that this new test facility was

extremely flexible. The engine could be operated as a

triple-expansion condensing engine or run in a variety of other ways.

In Paper 56 read to the Institution of Civil Engineers in December 1889,

Reynolds described with some pride the large triple-expansion steam

engine which had been installed under his close supervision in the

Whitworth Engineering Laboratory at Owens College (see Figure 16).

Characteristically, Reynolds ensured that this new test facility was

extremely flexible. The engine could be operated as a

triple-expansion condensing engine or run in a variety of other ways.